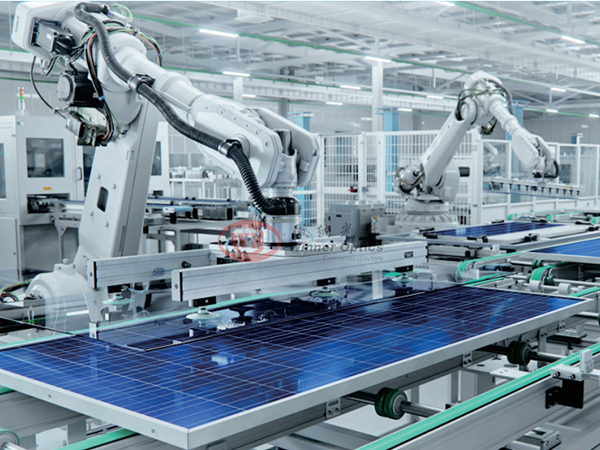

Industrial

Automation

Yepamusoro-chaiyo magetsi / manyore yekumisikidza matanho anoita basa rakakosha mumunda weindasitiri otomatiki.Aya matanho ekumisikidza akagadzirirwa kunyatso fambisa uye kuisa zvinhu zvine hungwaru uye kudzokororwa, zvichiita kuti zvive zvakanaka kune akasiyana maapplication mumaindasitiri akadai sekugadzira, marobhoti, semiconductor, uye tsvagiridzo.

Imwe yemashandisirwo ekutanga epamusoro-chaiyo yekumisikidza nhanho ndeyekusangana uye kugadzira maitiro.Aya matanho anogonesa kurongeka kwakanyatso uye kuiswa kwezvikamu panguva yekuungana, kuve nechokwadi chechokwadi uye chakaenderana mhando yechigadzirwa.Semuenzaniso, mukugadzira zvemagetsi, matanho aya anoshandiswa kuisa mabhodhi edunhu, zvinhu zvekutengesa, uye michina yekuyedza ine micron-level chaiyo.

Mumunda wemarobhoti, yakakwirira-chaiyo yekumisikidza nhanho inoshandiswa kurobhoti ruoko kutonga uye kunyengera.Anoita kuti marobhoti aite mabasa akaoma kunzwisisa anoda kunyatsomira, akadai sekusarudza nenzvimbo, kubata zvinhu zvisina kusimba, uye kubatanidza zvinhu zviduku.Matanho anopa kugadzikana kunodiwa uye kurongeka kuti ive nechokwadi chekuti robhoti yekupedzisira-effector inosvika panzvimbo yaidiwa nepamusoro kudzokorora.

Mune iyo semiconductor indasitiri, uko miniaturization yakakosha, yakakwirira-chaiyo yekumisikidza matanho akakosha pakuongorora wafer, lithography, uye kurongedza maitiro.Aya matanho anobvumira kunyatsofamba uye kurongeka kwewafers, masks, uye zvimwe zvikamu, kuve nechokwadi chekugadzirwa kwepamusoro-soro akasanganiswa maseketi.

Marabhoritari ekutsvagisa nekusimudzira anobatsirwawo kubva kumatanho epamusoro-chaiyo yekumisikidza.Aya matanho anoshandiswa mukuedza kwakasiyana kwesainzi, senge microscope, spectroscopy, uye nanotechnology research.Vatsvaguri vanogona kunyatso kumisa samples, probes, uye zviridzwa, zvichivagonesa kudzidza nekushandisa zvinhu padiki uye nanoscale mazinga.

Uyezve, yakakwirira-chaiyo yekumisikidza nhanho inowana maapplication mumetrology uye kudzora kwemhando.Iwo anoshandiswa kuyera kuyerwa, calibration, uye kurongeka kwemaoptical masisitimu, masensa, uye zvimwe zviridzwa chaizvo.Aya matanho anopa kugadzikana kunodiwa uye kurongeka kunodiwa kuyera kwakaringana uye maitiro ekugadzirisa.

Panyaya yekushanda, yakakwirira-chaiyo yekumisikidza nhanho inogona kudzorwa nemaoko kana nemagetsi.Matanho emaoko anowanzo shandiswa mumashandisirwo apo kugadziridzwa kwakanaka uye kutonga kwemushandisi kunodiwa.Iwo anowanzo ratidza micrometer kana vernier zvikero zvechaiyo chinzvimbo kuverenga uye mavhiri emaoko ekugadzirisa manyore.

Magetsi ekumisikidza matanho, kune rumwe rutivi, anopa otomatiki uye programmable control.Iwo anogona kubatanidzwa muhombe otomatiki masisitimu uye anodzorwa kuburikidza nemakomputa interface kana programmable logic controllers (PLCs).Matanho emagetsi anopa kunyatsojeka, kudzokororwa, uye kumhanya zvichienzaniswa nematanho emaoko, zvichiita kuti ive yakakodzera kune yakakwirira-yekugadzira nharaunda.

Mukupedzisa, yakakwirira-chaiyo magetsi / manyore yekumisikidza matanho ane yakakura maapplication muindasitiri otomatiki.Kugona kwavo kupa kwakaringana uye kudzokororwa chinzvimbo kunoita kuti ive yakakosha mukuungana, marobhoti, semiconductor kugadzira, marabhoritari ekutsvagisa, metrology, uye kutonga kwemhando.Aya matanho anobatsira mukuvandudza chigadzirwa, mhando yechigadzirwa, uye kugona mumaindasitiri akasiyana, kutyaira kufambira mberi mune otomatiki uye tekinoroji.